By Bill Bregar

SENIOR STAFF REPORTER

Published: July 15, 2014 4:22 pm ET

Updated: July 15, 2014 4:25 pm ET

Image By: Sidel Group

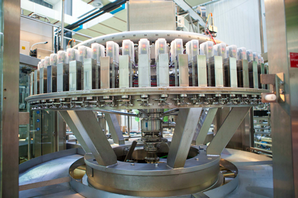

The Sidel equipment allowed Galanz to reduce bottle weight significantly

Sidel Group has supplied a SBO heat-resistance blow molding machine and a Matrix hot filler to the first hot-fill line with slurry dosing to be installed in Kazakhstan and central Asia, saving Galanz Bottlers $1.4 million a year.

The Sidel equipment allowed Galanz to reduce bottle weight significantly, cutting PET resin use by 700 metric tons a year. The company went to a short neck, and redesigned the bottle, to save about five grams of material per half-liter bottle, and around 10 grams for the 1.2-liter bottle.

Galanz Bottlers was awarded a contract to bottle hot-fill Nestle’s Nestea in Kazakhstan, so the company needed to expand production and rethink its existing production process, according to Sidel. The bottling company is based in Almaty, Kazakhstan.

The Sidel equipment is a SBO14 Universal2eco HR (heat resistance) blower and a Matrix SF 700 ISM Hot Filler.

Galanz is turning out bottles at speeds of up to 24,000 bottles per hour.

Sidel, a division of Tetra Laval Group, is in Hünenberg, Switzerland.

The North American unit, Sidel Inc., is in Norcross, Ga. |